Products

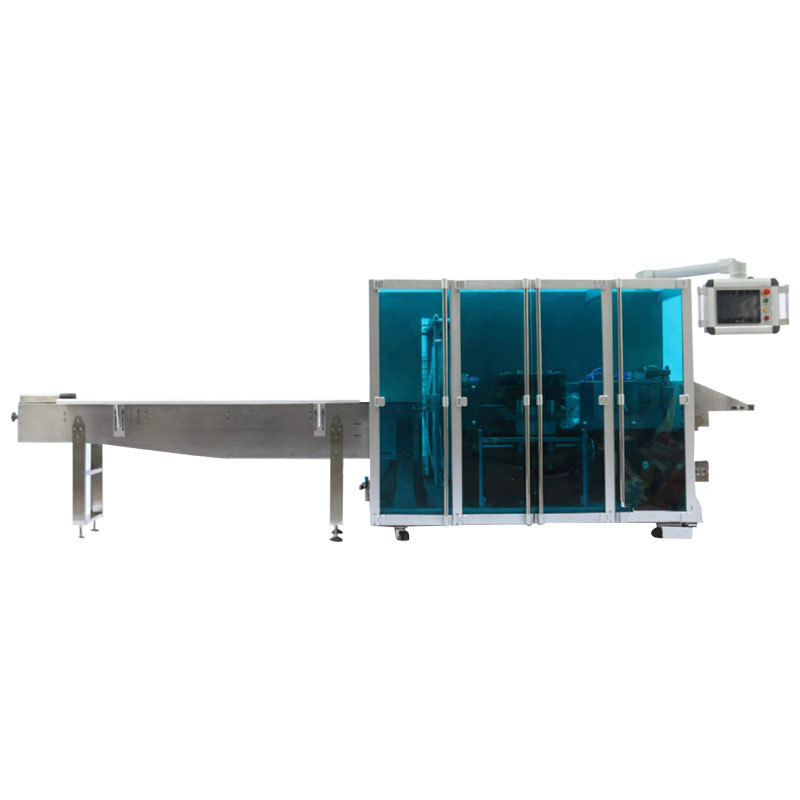

HD-SJT25 Water Gel Coating Machine

Keywords:

| HD-SJT25 Water Colloid Coating Machine | |||||

| Model: | HD-SJT25 |

Coating Width: |

≤220mm |

Coating Thickness: |

0.5-1mm |

|

Design Speed: |

5m/min |

Cross Cutting/Roll Cutting Width: |

250mm |

Working Air Pressure: |

0.6Mpa |

|

Total Power: |

6.5KW |

Power Specifications: |

220V/50Hz |

Appearance Dimensions: |

5200*1140*1800mm |

|

Net Weight: |

1000kg |

|

|

||

| Usage and Features | |||||

|

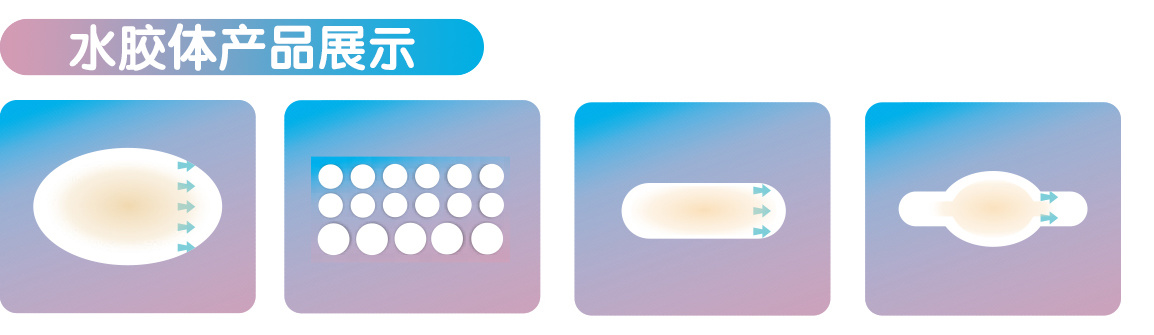

Features: Coating, forming, waste shaving, and cutting of water colloid products. |

|||||

Usage methods and precautions for the water colloid coating machine:

1. Preparations before starting the machine

1. Check if the electrical switches and wiring are loose or damaged.

2. When stopping at normal temperature, pass through the traction belt according to the process circuit requirements.

3. Start the exhaust equipment.

4. Confirm that there is no open flame (such as electric furnace, etc.) in the coating room.

5. The control cabinet of the coating machine and the shell of the drying box must be reliably grounded.

2. Guidance program during startup

1. Turn off the main power switch and power switch on the control cabinet.

2. Set the initial value (usually 180~280) and frequency division (usually 20~50) on the tension controller.

3. Set the coating working mode and related parameters (coating speed, length, gap length, roller speed ratio, etc.), then turn on the compressed air (adjust the pressure regulating valve of the pneumatic control box to make the pneumatic pressure between 0.2~0.3MPa);

4. Start the drying fan and drying temperature controller.

5. Turn on the power of the automatic correction and tension controller.

6. Ensure that the equipment temperature meets the process requirements;

7. Feed the hopper of the water colloid coating machine while starting the coating machine for coating.

3. Shutdown procedure for the water colloid coating machine

1. Confirm that the coated electrode sheet has been wound, then stop the machine.

2. Turn off the power of the equipment heater, and when the temperature of each section drops below 60, stop the dry wind and other fans.

3. Stop the compressed air.

4. Disconnect the power on the rectifier cabinet and control cabinet.

The difference between gel paste and ordinary paste lies in the dosage, comfort, and skin irritation. It is recommended that patients choose the appropriate patch based on their specific needs and economic capabilities to aid in disease recovery.Previous

Previous

Hydrocolloid dressing machine

Related Products

Online consultation

If you are interested in our products, please leave your email and we will contact you as soon as possible

Beijing XinyiHuida Electromechanical

E-mail: xinyihuida@163.com

Mobile: +86-13911770565 Mr. Lin (General Manager)

Address: 415, 4th Floor, No.2 Jinguangnan Street, Jinguangnan Street, Xilu Street, Fangshan District, Beijing

Product Category

Copyright© Beijing XinyiHuida Electromechanical Equipment Co., Ltd